Dimensions

Approx. 2,800/2,550 mm = raised platform at front incl. frame offset

Approx. 5,800 or 6,400/2,550 mm = drop-deck platform – flat load surface or external surfaces advanced

Approx. 800/2,550 mm = rear access slope

Total width: approx. 2,550 mm or approx. 3,000 mm with extension

Loading height, laden: approx. 920 mm

Frame

Welded steel construction with flat front frame offset or body offset

and drive-on taper at rear with externally welded square ribs

4 pairs of mounting pockets for 100 x 50 mm tubular steel posts in external frame

Recess in access slope for excavator shovel linkage

5 pairs of lashing points in external frame

2 pairs of recessed lashing rings in floor

Lubrication strip for front axles and turntable at front

Lubrication strip for rear axles and ramp at rear

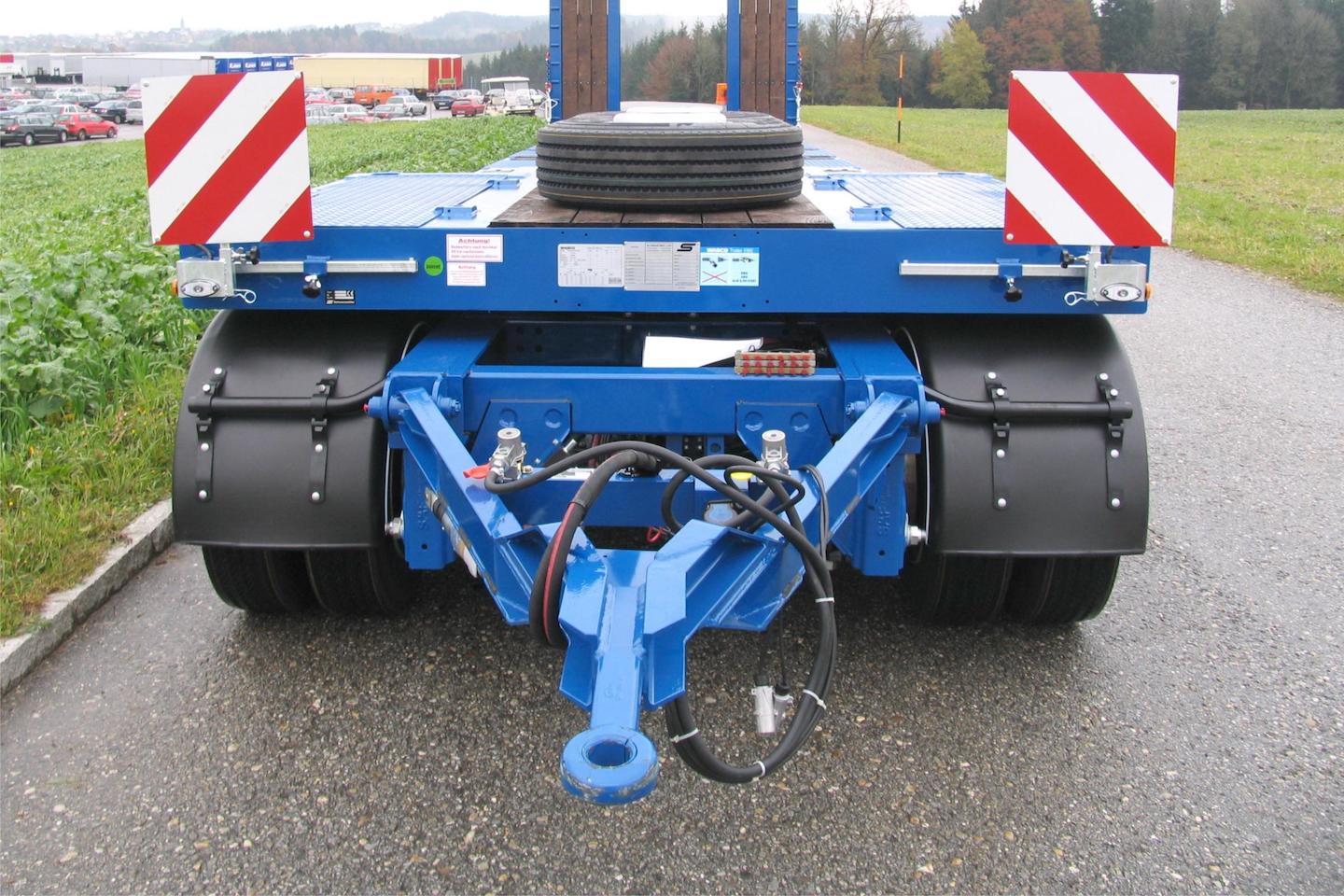

Chassis

Air suspension with lifting and lowering device on rear axles (for loading and unloading)

Automatic adjustment of driving level from 15 km/h

Low-loader axles, each with 11 t axle load at 80 km/h

S-cam brake 300/200 mm, autom. brake linkage adjuster

1st to 4th axle rigid

Steering knuckle 5th axle = friction-steered trailing axle

(12° steering angle) incl. electropneum. reverse gear interlock with switch operation in cab and additional operation on chassis

Autom. lifting 3rd axle = raised or lowered autom. according to weight (with the lifting axle raised, the loading height or total height increases by approx. 50 mm) and forced lowering for autom. lifting axle with button operation in cab

Tyres :

20 x 245/70 R 17.5 143J, manufacturer as per factory specifications

20 steel wheel rims 6.75 x 17.5, 10-hole, with rim offset, silver ex-works

Drawgear

Fixed drawbar, 50 mm heavy-duty drawbar eye,

with silent bushing

Brake system

Brake system according to EC Directive 71/320 or ECE R13

Two-line brake

EBS – electronic brake system (Wabco 4S3M)

Spring-loaded parking brake

Steel air tank