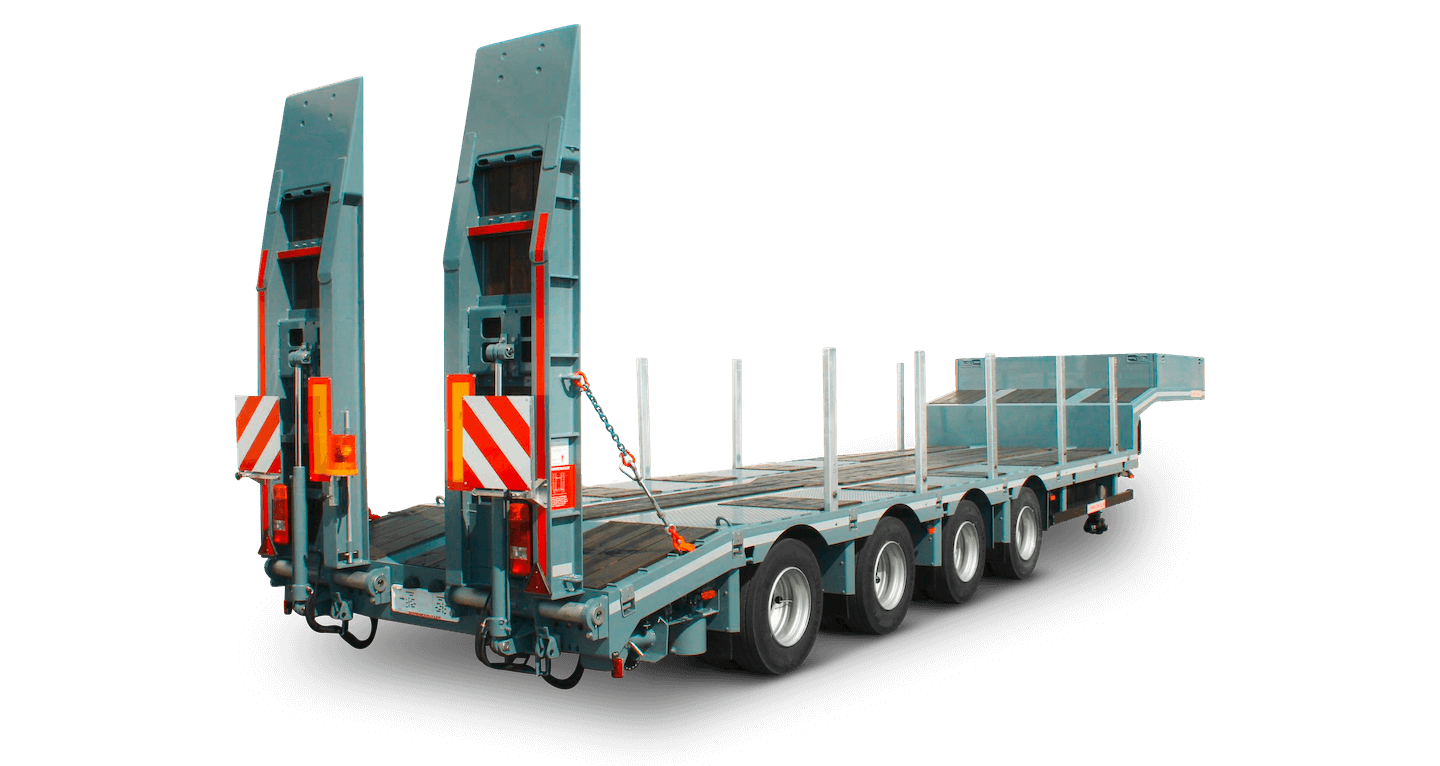

Dimensions

approx. 3,500/2,550 mm or approx. 2,480 mm between side walls = front offset platform

Approx. 8,300/2,550 mm = drop-deck platform – flat load surface

Approx. 1,000/2,550 mm = rear access slope

Total width: approx. 2,550 mm or approx. 3,000 mm with extension

Loading height, laden: approx. 900 mm

Horizontal position of semitrailer at fifth-wheel height: laden approx. 1,220 mm

Frame

Welded steel construction with tapered frame offset at front

and drive-on taper at rear

Replaceable 3.5″ kingpin (slew radius on truck at rear max: 2,100 mm)

5 pairs of mounting pockets on drop deck incl. tubular posts 100 x

50 x 5

mm, useful height approx. 1,000 mm, hot-dip galvanised

5 pairs of lashing points on external frame

10 recessed lashing eyes in the drop-deck section

Storage for extension planks below loading platform when not in use

Chassis

Air suspension with lifting and lowering device, for loading and unloading

Automatic adjustment of driving level from 15 km/h

Air-sprung low-loader unit with low-maintenance axles.

4 x 10 t, (technical 4 x 12 t) wheelbase 3 x 1.310 mm.

S-cam brake 300/200 mm, autom. brake linkage adjuster.

1st and 2nd axles rigid,

Third and fourth axles steering knuckle = friction-steered trailing

(20° steering angle) incl. electropneum. reverse gear interlock with switch operation

in cab and additional operation on semitrailer.

Lifting first axle = raised or lowered automatically according to weight (with the lifting axle raised, the loading or total height increases by approx. 50 mm) as well as forced lowering autom. lifting axle, incl. integrated speed-restricted moving-off,

with button operation in cab (no button on our part)

Tyres :

16 x 245/70 R 17,5, 146/146F, manufacturer as per factory specifications

16 steel wheel rim, 10-hole, with rim offset, silver ex-works

Support fixtures

Mechan. 2 x 12 t support jacks, single-sided operation and thrust compensation