For pallet and grain transport etc.

Weights

Gross train weight (perm.): 40 t

Gross weight (techn.): 39 t

Axle assembly load (techn.): 27 t

Fifth-wheel load (techn.): 12 t

Payload: approx. 25 t

Tare weight: approx. 8, 9 t

Dimensions

Internal length: approx. 13,400 mm

Internal width: approx. 2,460 mm

Internal height: approx. 2,200 – 2,400 mm

Total width: 2,550 mm

Total height, unladen: approx. 3,800 – 4,000 mm

Loading height: approx. 325 mm over fifth-wheel height

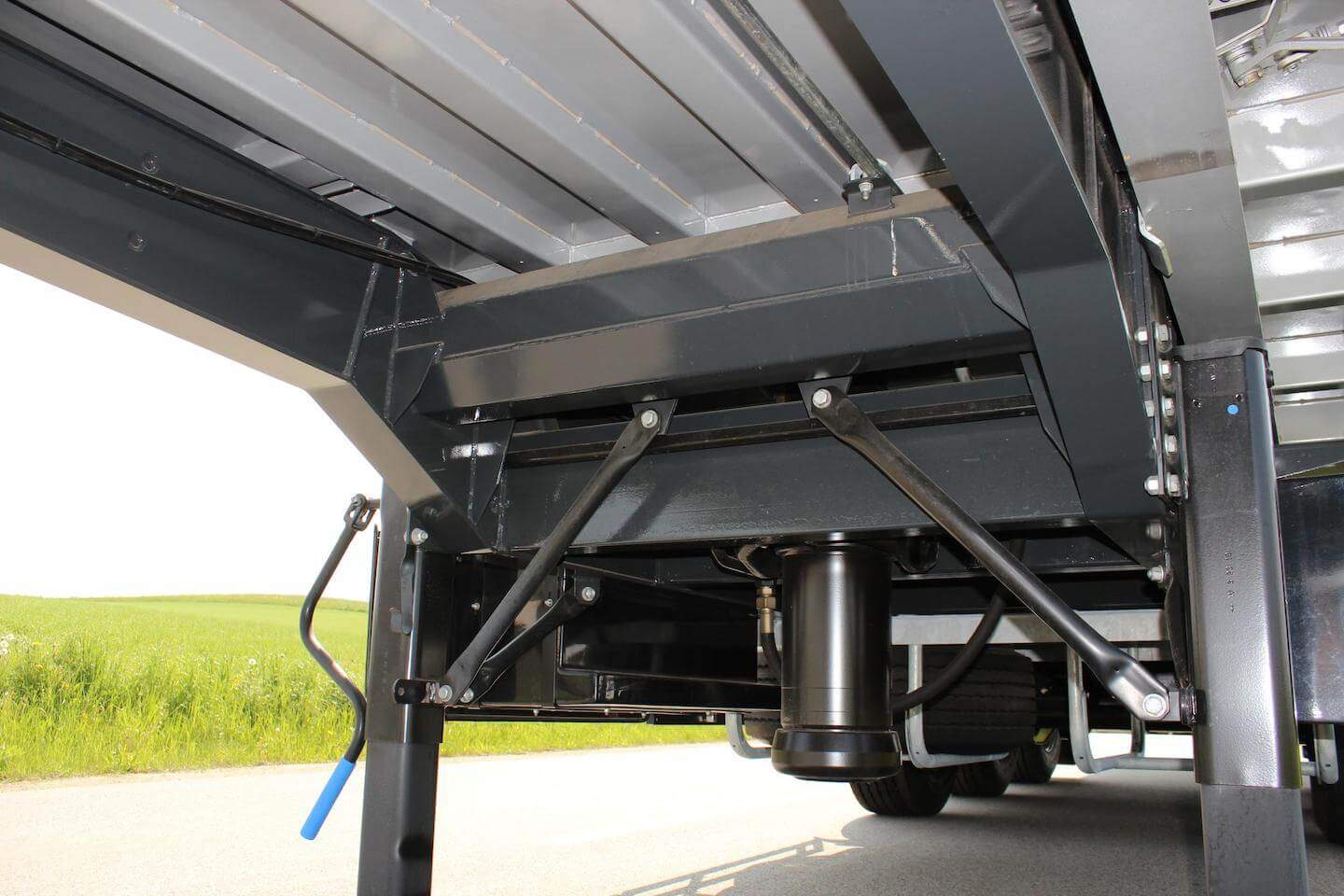

Frame

Naxtra welded steel frame construction – low design height

Connector lock for tipper body with cross-over protection

Replaceable 2″ kingpin

Chassis

Air suspension with autom. lowering device via inductive switch and lowering lock via rotary switch on semitrailer

air suspension unit with low-maintenance 430 mm disc brake axles, 3 x 9 t rigid, wheelbase 2 x 1,310 mm

Tyres :

6 x 385/65 R 22.5 160J, manufacturer as per factory specifications

6 steel wheel rims 11.75 x 22.5, 10-hole, with rim offset, silver

Support fixtures

Mechan. 24 t support jacks with single-sided operation, low-maintenance

Brake system

Brake system according to EC Directive 71/320 or E CE R13

Two-line brake

Spring-loaded parking brake on 2 axles

EBS – electronic brake system

Wabco 2S2M = one axle sensed

RSS – stability program

Steel air tank

Tipping system

2 special tipper cylinders for 3-way tipping, installed in series

1 arrester cable

Rearward tipping angle: approx. 34°

1 pipe system with screw coupling DN20

Tipping loading ramp

Full-steel welded construction with fine-grained special steel floor panels, 5 mm

(slight floor unevenness possible due to weld distortion)