Weights

Gross weight (techn.): 20 t

Payload: approx. 15.3 t

Gross weight (perm.): 18 t

Tare weight: approx. 4. 6 t

Dimensions

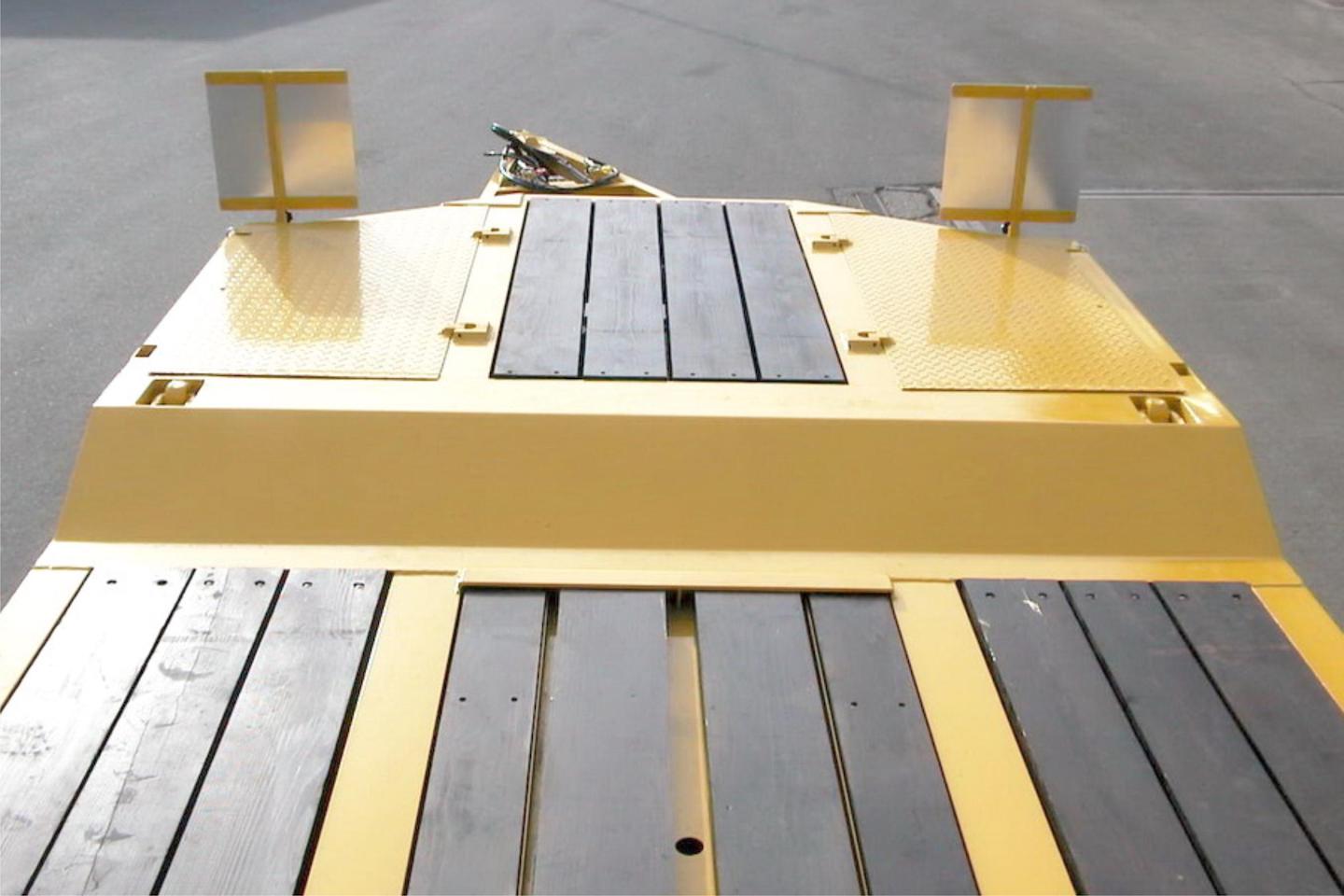

Approx. 2,100 mm raised platform at front incl. frame offset, tapered corners

Approx. 4,500 mm = drop-deck platform – flat load surface

Approx. 1,000 mm = rear access slope

Total width: 2,550 mm

Loading height, laden: approx. 870 mm

Frame

Welded steel construction with flat front frame offset or body offset

and drive-on taper at rear

4 pairs of lashing points in external frame

2 pairs of recessed foldable 5 t lashing rings in floor (10 t techn. tensile strength)

Chassis

Reinforced, maintenance-free parabolic springs

Low-loader axles, each with 11 t axle load

S-cam brake 300/200 mm, autom. brake linkage adjuster

Tyres :

8 x 2 4 5/7 0 R 17.5 14

3 J, manufacturer as per factory specifications

8 steel wheel rims 6.75 x 17.5, 10-hole, with rim offset, silver

Drawgear

Fixed drawbar, 1,800 mm long, 40 mm drawbar eye, 5° angle,

with silent bushing

truck superstructure up to 500 mm

Truck coupling height, unladen: approx. 850 – 900 mm

Brake system

Brake system according to EC Directive 71/320 or E CE R13

Two-line brake

EBS – electronic brake system

Wabco 4S3M = both axles sensed

Spring-loaded parking brake on 2nd axle

Steel air tank